A Professional manufacturer of digital printing material and display products

A Professional manufacturer of digital printing material and display products

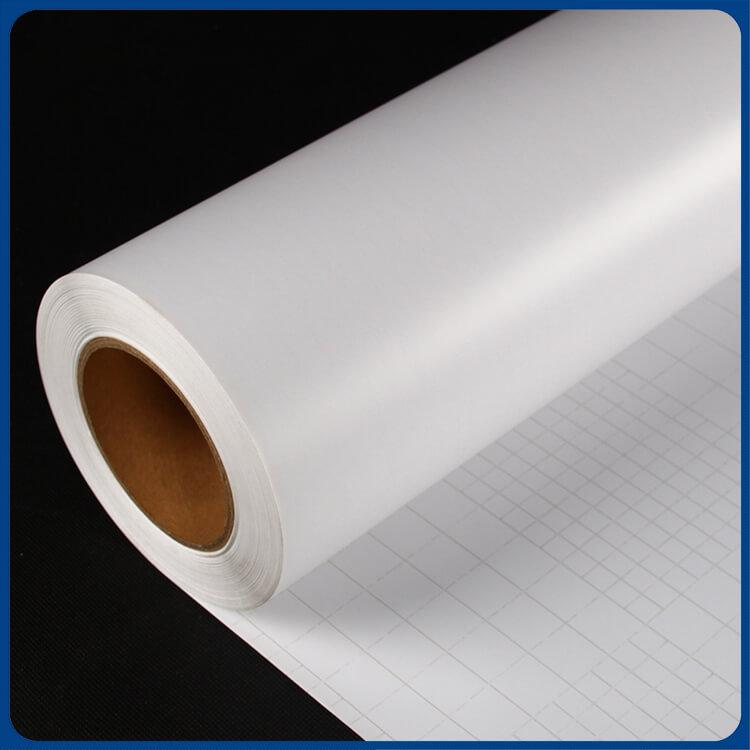

Cold laminating film is made of transparent PVC by the adhesive processing, according to the membrane surface texture can be divided into glossy film, matte film, frosted film, astral membrane, laser film and special texture of the protective film. The major using in advertising production is the glossy film, matte film and frosted film. Cold laminating film with manual or cold mounted machine mounted in the photo print on the screen, to avoid the screen (print side) was scratched, polluted or wet, play a protective screen role.

Cold laminating film can increase the texture of the screen and protect the screen, and is resistant to scratching and water resistance. However, it can not make the photo image with a high degree of corrosion resistance and anti-ultraviolet erosion, UV will wear cold laminating film to make the screen fade, and after a long time, cold laminating film will brittle. Can be widely used in wedding phase, oil painting, calligraphy and painting, outdoor posters, advertising, all kinds of pictures, documents, information and so on. Now can provide more than 20 models, all kinds of patterns, light / matte and laser series and other products. Using in larger advertising, architectural decoration renderings, background decoration, etc., which protect the photos better with using the cold laminating film.

Using method

1.Pressure regulator

(1) Turn the regulator on both sides of the machine and make the upper and lower shaft separation. It should be put the mounted photo and cold laminating film at the same time into the two shafts, turning the regulator handle, so that the upper axis parallel down Move. When the rotating pressure control handle suddenly feel relaxed, the next two shafts have been in contact, then do not continue to press down, simply press the handle gently with tight. If you continue to pressurize, the shaft will be deformed and the operation will fail

(2)After the pressure is adjusted, make the figure and cold laminating film exit from the two axes. Ready to mount the cold laminating film.

2.Mounted

(1)Mounting diagram (within 1.5 meters)

Will be cut off the cold laminating film (should be slightly larger than the figure) into the two shafts (film down, the separation of paper in the following), cold mounted machine is the front of the two-axis pressure. the film and release paper Separate, then the film pulled to the rear of the machine, wrapped in the roller, the release paper flat on the front work panel, near the axis of the site, hand pressure isolation paper, so that the film and isolation paper as far as possible, will be mounted the figure is placed on the release paper, the hand from the top of the figure to the middle of both sides of the flat. Turn the machine, evenly pressed into the two rollers. Do not push only the sides of the graph, do not pay attention to the front of the figure parallel into the shaft, or be pressed into the shaft part. That will gradually appear wrinkle phenomenon, resulting in failure. If you do not grasp the parallel drawing into the shaft, you can use 1 cm wide double-sided adhesive tape (2-3 cm in length) in three to four points to the front of the figure and the release paper stick together, Live in the middle and then gradually to both sides of the paste.

(2)Mounting large image(1.5 meters above)

In the installation of more than 1.5 meters of the map, the most important thing is to prevent the sketch with the film. Just into the shaft part of the difference is not bad, can be a length when it will be absurd. So the operation method must be appropriate. Production of long chart when the first axis to upgrade to achieve the maximum degree of promotion. Secondly, the cold laminating film and the map overlap together, cold mounted film on the map in the next (cold mounted film on the surface, Isolated paper on the back, rolled into a cylinder, put one end on a clean ground, or poke on the table, hand pinch, do not let the film misplaced, the cold mounted film and the figure at the same time into the two axes. Between the need to have a person in front of the machine to catch the front of the map and cold laminating film sent to prevent loose dislocation, as far as possible in the machine is put and then move the axis down parallel to the pressure adjustment In order to ensure that the drawings and the film is not biased, you can turn the machine first, try to go again, but do not get out of the shaft. If you do not skew, you can stop the rotation in any one position, and lift the Lengbiao film at one end. Cut the separation paper with scissors (be careful not to cut the film), then turn it off. Eversion to the other side, turning the machine while rotating on the axis while continuing The film was peeled off, the film was mounted on the map, the above part is completed, and then reverse the machine with the same method to the other side of the map also mounted on the film, this is the completion of this work The

(3)Mounted the mounted image on the decorative board

First of all to double-sided adhesive tape is attached to the back of the mounted cold-mounted film. Double-sided adhesive tape can be attached to the above method with the above mounted laminat film of any of the two methods will be a good double-sided adhesive on the decorative plate on the board, the machine axis up, the board together with the map Put the two shafts between the adjustment of the pressure (pressure adjustment in the next section) and then one end of the double-sided adhesive tape peeled off the reverse folding, and cut a part of the rotating machine to be stripped off the paper Part of the sticky board. And then the part has not been pasted to the other side of the shaft, turn the machine and continue to peel off the paper (with the production of large map method), the figure will be pasted on the decorative board above several methods need to operate In practice, continue to explore the experience, the beginning of the operation may feel inconvenient, and even operation failure, then carefully find out the reasons, mainly in the operation method to find out the reasons to reduce the failure to improve the success rate, the saying goes familiar. After careful operation, will soon be skilled here to remind the attention of the long-term if you often make long plans, you should buy a high degree of automation, performance, stability, easy operation, do not take up the space of the cold mounted machine. If you can install the whole volume of the film, the machine automatically separated when the rotation, winding isolation paper, and even can be completed at the same time cold laminating film and double-sided adhesive paste. And can be mounted on the film roll the whole volume rolled up. Operation is very simple, is the ideal post-production equipment.